As production processes across all industries become more automated, critical links can be made by engineered cranes to integrate separate parts of a process. Whatever the application, you are bound to need a link for unloading, transfer, feeding, storage, setup or loading. The target is increasing efficiency, throughput and safety ultimately leading to reduced business costs.

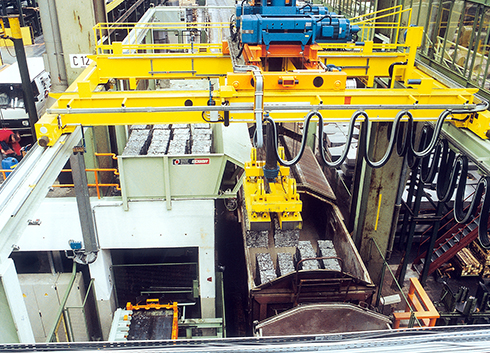

Process linking involves providing the optimum material flow interface between the point of arrival into the crane coverage area through to the point of despatch from the area. It may involve just in time or first in first out inventory control, batching or stock rotation. Typically, material or products may be buffered in a store before onward processing, this can be managed manually, semi or fully automatically with integrated warehouse management systems.

Smooth drive characteristics coupled with load management systems such as anti-sway, load dependant hoisting speeds increase the material flow rates, reduce loading and set up times and ensure ultimate control whatever the load.

Process linking often involves providing the right lifting attachments and MHE-Demag has a comprehensive range of customised lifting equipment specifically aimed at fulfilling each task. The efficient, safe handling of loads increases productivity. A well designed attachment will help you to move loads quickly and safely, better utilise storage capacity and minimise product damage.

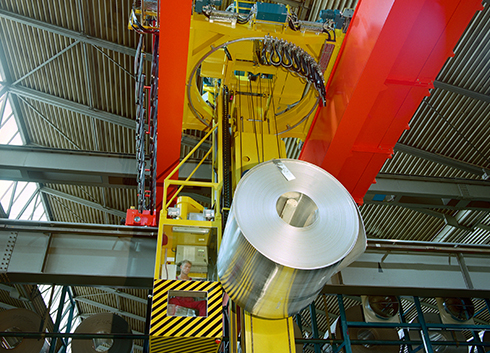

The increasingly shorter production times in the automotive industry pose great challenges for manufacturers and suppliers to meet the just-in-time demands of logistics operations. This means that material handling components used in production have to offer a high level of availability, since the failure of just one important component may have a considerable financial impact on the overall production process.

Our engineered cranes transport, turn, pivot and lift loads into optimum assembly positions and satisfy operators demands for precise positioning throughout the process. At the same time, they are used wherever press tools for car body parts have to be handled or heavy injection moulding tools have to be changed, for example in the production of plastic parts. In assembly operations, hoist units help to provide ergonomically favourable, as well as efficient, workplaces for workers. Whether the cranes are required for delivering the steel coils to the de-coiler, sheet blanks to the press tool or for the storage management of the press tool dies themselves, MHE-Demag has the experience and the solution.

We have the solution from special attachments to interface with your load, positioning and anti-sway control, remote operation stations, condition monitoring and warehouse management solutions, all of which can seamlessly linked for fully automatic control and to interface with your own systems.