Maintenance, Repair and Overhaul (MRO) facilities are becoming increasingly complex and accommodating more aircraft types. In many cases, the material handling requirements demand specially developed solutions. Crane systems play a supporting role in the construction and maintenance of aircraft all over the world. Cranes are used for both manufacturing components as well as for the in-house transport of sub-assemblies, up to and including complete aircraft fuselage. As area-serving, overhead transport and handling systems, they link the individual steps in assembly. Greater cost savings can be achieved the more closely they are designed to meet individual process requirements. As a partner who has served the aircraft industry for decades, MHE-Demag has extensive expertise in the planning and manufacture of crane solutions that are precisely matched to process requirements for the safe and reliable transport and precise positioning of sensitive aircraft components. Our customers benefit in many ways: the considerable increase in cycle rates boosts productivity. The use of standardised sub-assemblies also contributes towards the high availability of our crane installations. In addition, we provide solutions with ease of service and maintenance for cost-effective operation.

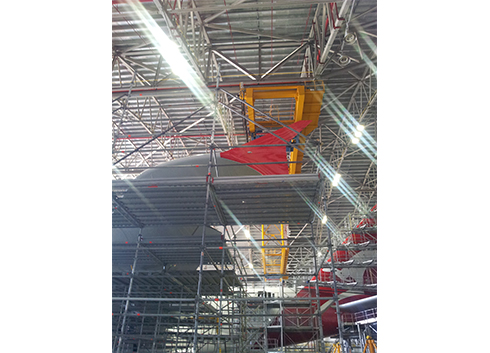

Flexible concepts for aircraft maintenance and painting, Telescoping Platforms (more commonly known as Teleplatforms) are a common tool used for positioning personnel at any point of the aircraft with precision, safety and reliability. High safety standards provide for smooth operation and prevent collisions with the aircraft. Precise control by means of a convenient control panel on the working platform for long and cross travel as well as for lifting, lowering and turning motions. All connections for tools and painting equipment are available on the working platform enabling personnel to reach virtually any part of an aircraft in a painting hangar. Additional flexibility is achieved by the ability to transfer the platform from one suspension crane to another, enabling the tight schedules for the painting processes to be met.

Since 1972 MHE-Demag has supplied the monorails, cranes and hoists for aircraft engine maintenance. These range from engineered cranes in a workshop to advanced maintenance lifting and turning systems for transporting todays largest engines from the maintenance cells into the engine test cell.

Engineered cranes designed for maintenance of aircraft in a hangar with a curved roof. The cranes are optimised to cover the aircraft being worked on in the hangar. Multi-span suspension cranes are an ideal solution for wide span buildings with a trussed roof structure supporting the crane in many suspended, parallel runways.